Characteristics of Polyurethane Sandwich Panel Production Line

Sandwich Panel Production Line - Fineagles Advance Engineering Plant : 6. IMES OSB, 10.St, No.22, Dilovası-Kocaeli, Turkey Office: İstanbul Sapphire, No. 4601 Istanbul, Turkey Email: [email protected] Phone: +90-212-809-61-16 Our Production lines World-class manufacturer of PU & PIR sandwich panel lines.

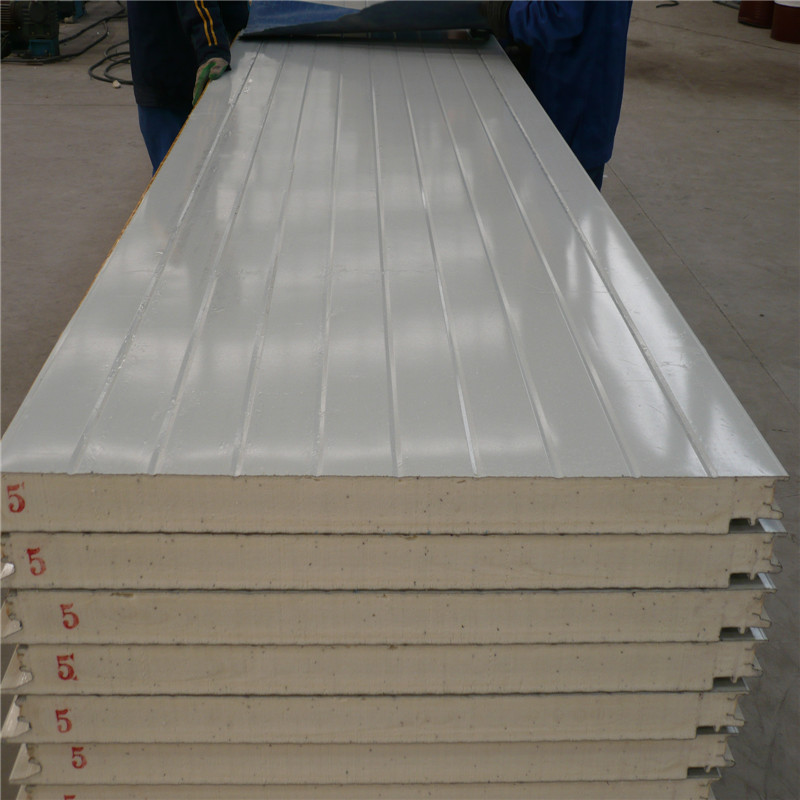

Polyurethane Sandwich Panel Production Line with CE China Sandwich Panel Roll Forming Machine

The PU sandwich panel production line is a marvel of modern engineering—a fully automated system designed to efficiently manufacture an array of exquisitely shaped and versatile polyurethane sandwich panels.

PU Foam Polyurethane Injection PU Sandwich Panel Production Line China PU Machine and PU

The PUR polyurethane sandwich panel production line forming machine system mainly consists of an upper forming machine, a lower forming machine, a press machine platform, and upper and lower interface raceways. It can also be designed according to the needs of customers. Archer Molding Machine Heating System:

China Polyurethane Sandwich Panel Production Line China Polyurethane Sandwich Panel

The PANELMASTER STEEL plant is designed for the continuous production of top-quality sandwich panels with different facings, panel thicknesses and profiles and the option of a core structure made of polyurethane or mineral wool.

Pu Polyurethane Sandwich Panel for insulated panels price realtime quotes, lastsale prices

Continuous sandwich panel lines Plant technology for the continuous production of polyurethane sandwich panels with a core structure made of polyurethane or mineral wool PANELMASTER STEEL More information Continuous insulation board lines

Automatic Aluminium PU Sandwich Panel Production Line Polyurethane Building Material

Especially Polyurethane Sandwich Panel Production Line (sandwich panel machine) is the automation equipment that can continuously and efficiently produce polyurethane sandwich panels of exquisite and diverse shapes. Moreover the Polyurethane Sandwich Panel Production Line (sandwich panel machine) consists of Un-coiler that inputs and releases.

Continuous PU Sandwich Panel Production Line Zhenjiang Sinowa Polyurethane Industrial

Long standing experience. Its great experience in the polyurethane business allowed TECNIP to supply complete COUNTINUOUS SANDWICH PANEL LINES. In order to ensure a high level production, TECNIP is constantly committed in R&D offering the most up to date technologies consultancy and tailor made solutions. Read more.

Low cost Pu Polyurethane Sandwich Panels realtime quotes, lastsale prices

The PU Sandwich Panel Production Line has revolutionized the construction industry with its production of polyurethane sandwich panels, known for their exceptional thermal conductivity and aesthetic appeal. This article delves into the characteristics and diverse applications of these panels, highlighting their significance in modern construction.

Discontinuous 120kW PU Sandwich Panel Production Line

Sandwich panels used in the construction sector provide buildings with thermal insulation as well as protection against external factors and and supply a solid, firm barrier. They are composed of composite, high resistance, low density foam filling material.

Polyurethane Sandwich Panel Production LineQuanlong Machinery is a Manufacturer and Supplier in

polyurethane sandwich panel manufacturing line complete equipment, mainly consisting of open system, film cutting system, molding machine system, steel preheating furnace, high-pressure foaming system, double-track system, double-track heating system, cutting system, horizontal cooling system, stacking system, packaging system and other equipment.

5M /min high quality polyurethane sandwich panel production line pu sandwich panel line hot sale

Our production plants are mainly dedicated to the manufacture of sandwich panels in polyurethane, mineral wool or polystyrene, normally covered by metal sheets. Our eps sandwich panel lines are built entirely in our facilities and are designed and developed to enable optimized, fast and accurate production.

5M /min high quality polyurethane sandwich panel production line pu sandwich panel line hot sale

The sandwich panel production line includes complete sets of equipment such as color steel plate unrolling, pressing, feeding (steel plate, polyurethane or rock wool), double track forming, finished product cutting, conveying, stacking, cooling (optional for customers), packaging, etc. It adopts microcomputer fixed-length counting device and new technology of field communication bus to realize.

Polyurethane Sandwich Panel Production Line is the automation equipment that can continuously

Polyurethane Sandwich Panel Line consists of Un-coiler that inputs and releases coil, Roll Forming Unit that makes shape of coil, PU Forming Unit that sprays PU solution, Laminating Unit that makes the shape of sandwich panel, Panel Cutting Unit that cuts the fabricated sandwich panel, Cooling Conveyor Unit that finishes products hardening the c.

Continuous Polyurethane (PU) Sandwich Panel Production Line China Polyurethane Sandwich Panel

Start Your Project sandwich panel production lines, high pressure dosing machine, trapezoidal sheet metal production, metal tile roof production line, flexible purlin machine, cut to lenght line machine

Sandwich Panel line & Sandwich Panel Machine of Ilkwang Metal Forming, including representative

Continuous PU / PIR Sandwich Panel Production Line, also called polyurethane sandwich panel manufacturing line/production line/machine, is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking and p.

Pu Polyurethane Sandwich Panel for insulated panels price realtime quotes, lastsale prices

Our sandwich panel production line system is a fully automation equipment system to produce various shapes of sandwich panels using a rigid-polyurethane foam or polyisocyanurate as a core material which is known as a top insulation in nowadays with low heat conductivity, heat reserving, anti-sweating, high strength durability and availability at.